- Home

- Solutions

- Products

- About Us

- Newsroom

- Contact Us

mcframe SIGNAL CHAIN automatically collects the real-time operation status from machines, new and old, using IoT devices attached to signal towers for utilization and OEE analysis. This quick-start solution pairs powerful capabilities with an efficient ROI.

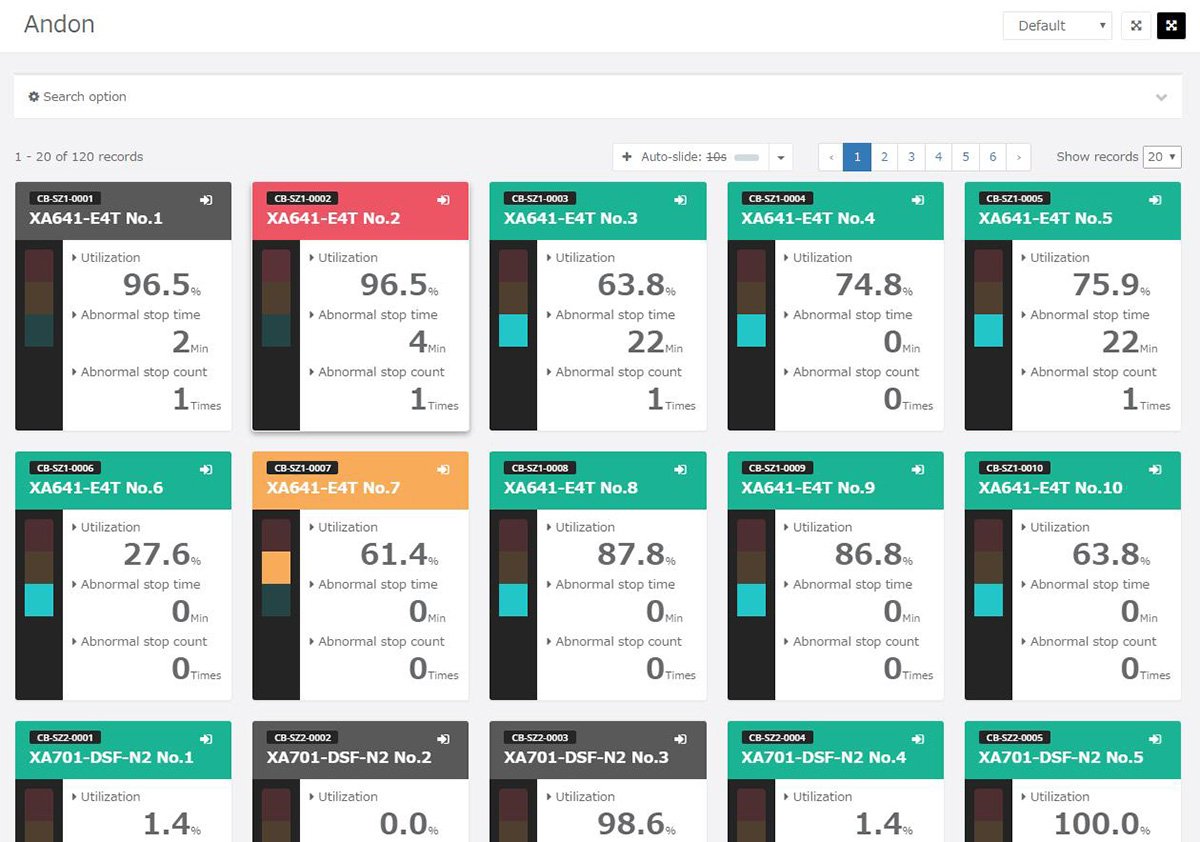

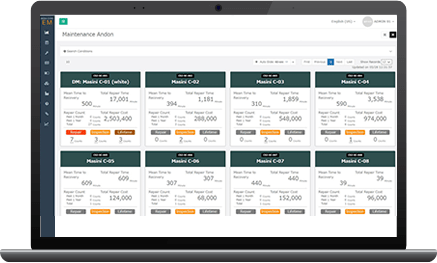

Clear visualization of real-time machine status that can amount to a 20% increase in productivity. Andon views can be conveniently grouped between plants, departments, lines, etc.

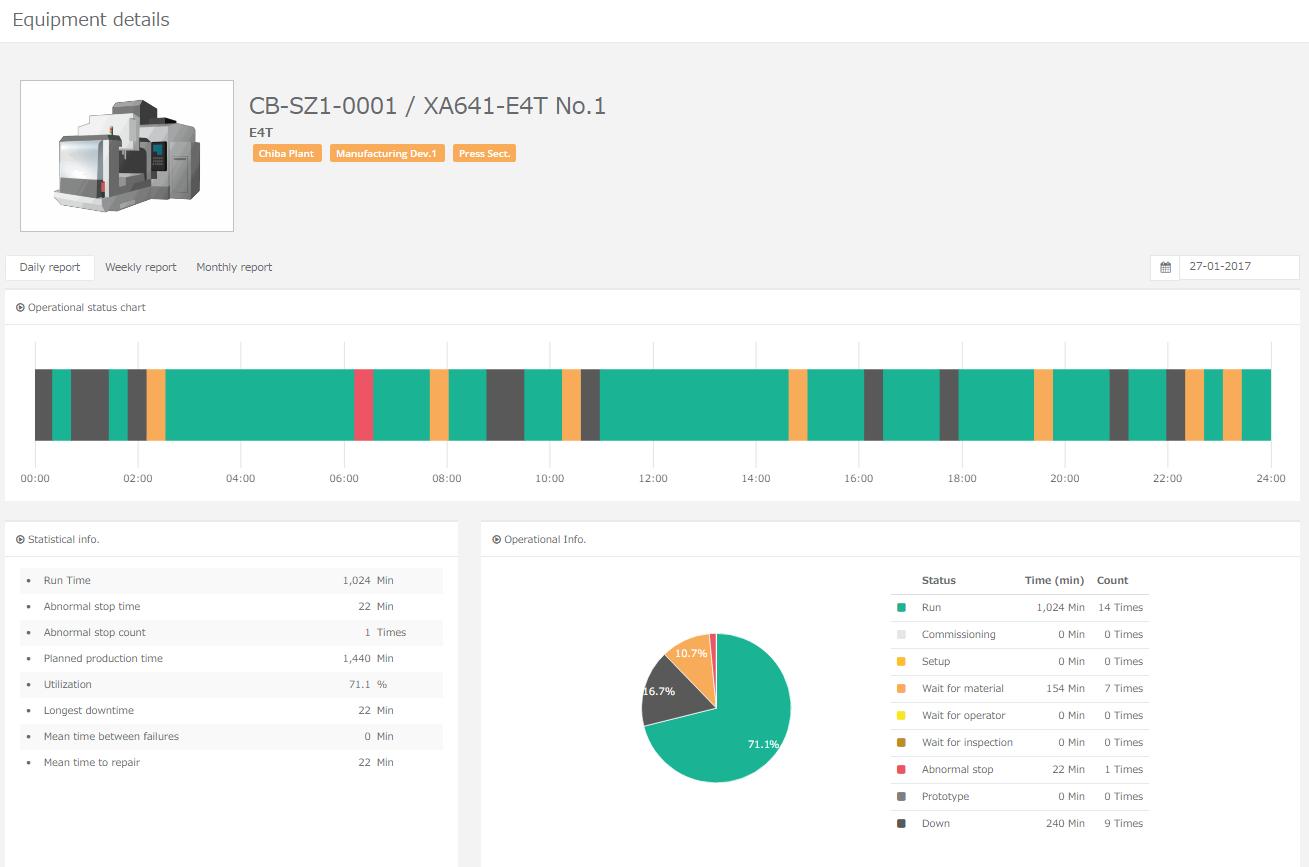

Daily, weekly, and monthly detailed records can be analyzed and evaluated to help identify operation trends and problems that were otherwise unnoticed.

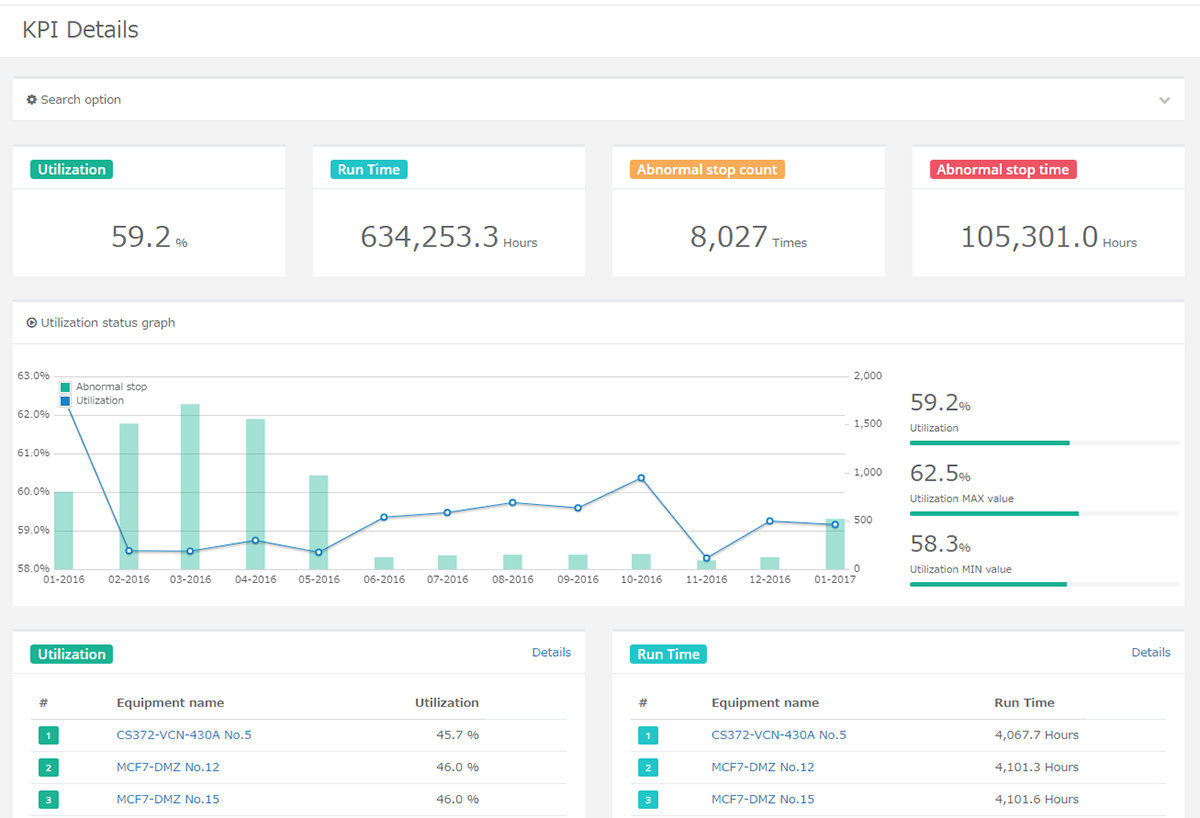

View Key Performance Indicators to analyze important operation statistics using summary conditions between lines, departments and more. Critical equipment is ranked by utilization, run time, stop time/count etc.

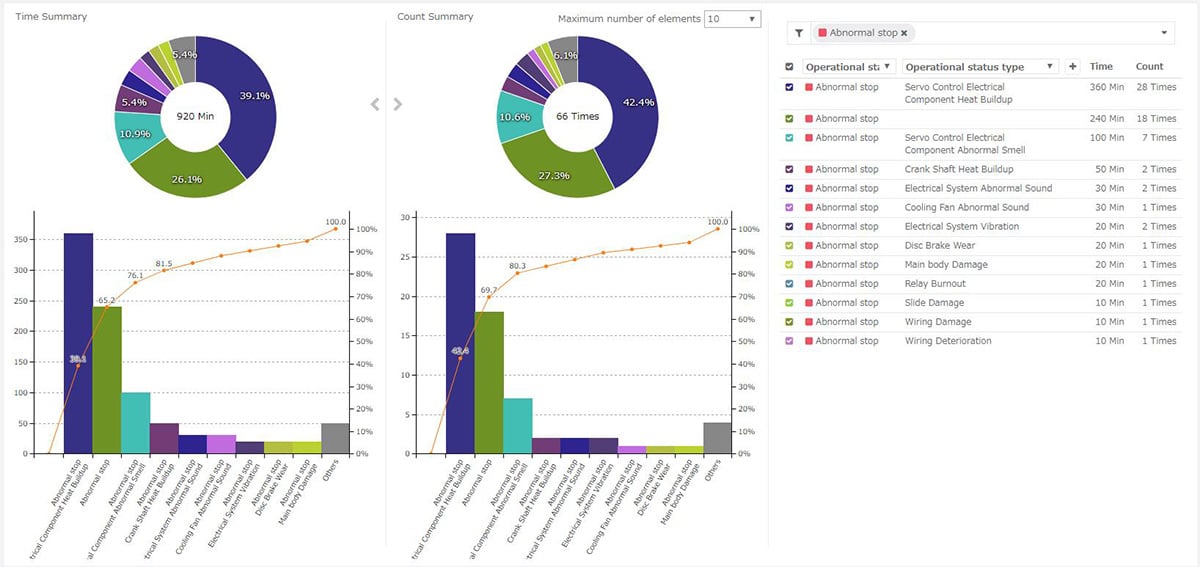

Easily identify downtime trends and frequently occurring problems. Recorded downtime causes can be analyzed for continuous improvement measures.

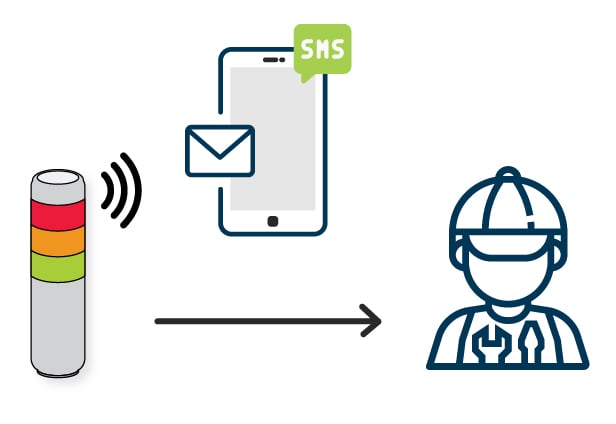

Set email or text alerts with detailed trigger conditions for quick reactions to stoppages and other time-sensitive occurrences. Send notifications to multiple personnel to guarantee transparency throughout the factory.

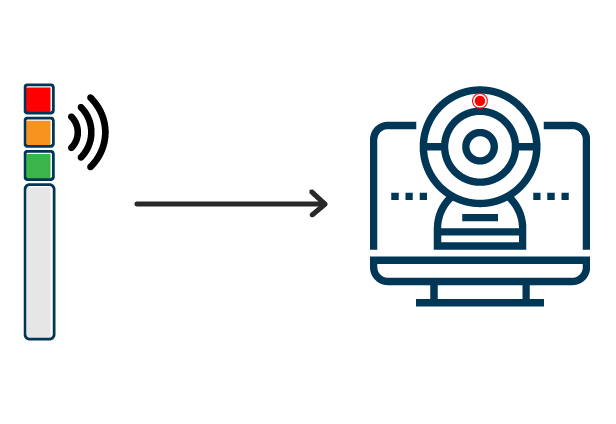

Automatically trigger video capture to record and the problems as they occur and boost response improvement measures.

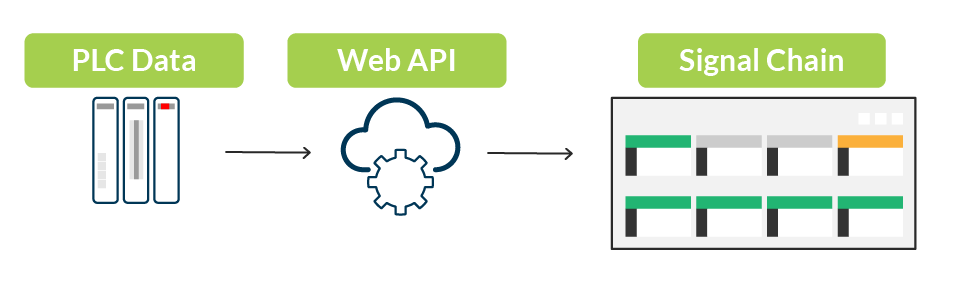

Connect to various other data hubs separate from the signal lights (PLC, HMI, etc.) through Web API. Acquired data is integrated in SIGNAL CHAIN in real-time.

Get an inside look at SIGNAL CHAINS's Operation Monitoring and Analysis features.

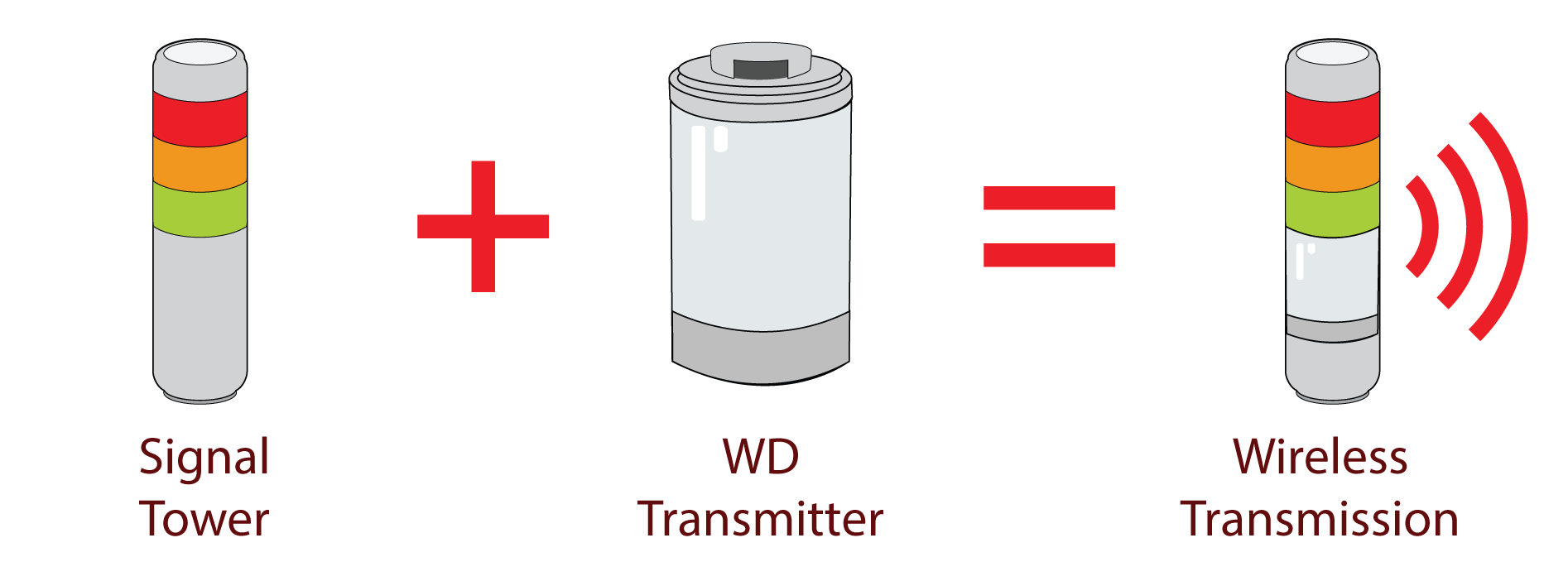

Wireless Transmitters attached to PATLITE signal towers send real-time status to WD receivers connected to a server (or cloud), aggregating data to be viewed and analyzed in mcframe SIGNAL CHAIN.

Learn more about PATLITE

A maintenance platform utilizing IoT to connect operations, workers, and equipment utilization data. Developed for global implementation, customization, and connectivity with the latest devices.

Learn more about SIGNAL CHAIN EM

Faced with issues such as limited visibility and delays in performance monitoring on the shop floor, Mid-States Aluminum, a leading aluminum manufacturer in Wisconsin, Illinois, overcame these challenges by implementing mcframe SIGNAL CHAIN.